What is the difference between adhesive force and displacement force-shear force? Or: Why won't my magnet on the wall hold the maximum weight?

-

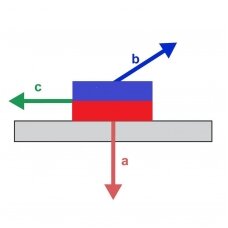

The maximum weight that a magnet can hold on a certain surface varies depending on the direction of the application of force.

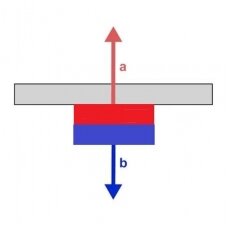

Our specified adhesive force applies to a holding strength vertical to the contact surface.

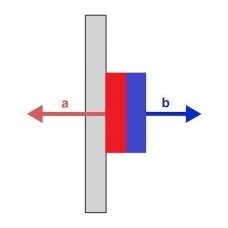

If the holding strength acts parallel to the contact surface (shear direction), its maximum value is much smaller (approx. 15-25% of the specified adhesive force).

These values may be improved with the use of special products from our shop and by experimenting with different surfaces.Holding strength vertical to contact surface

The maximum theoretical adhesive force that is specified for each magnet applies, among other factors, when the holding strength is at a right angle to the contact surface